|

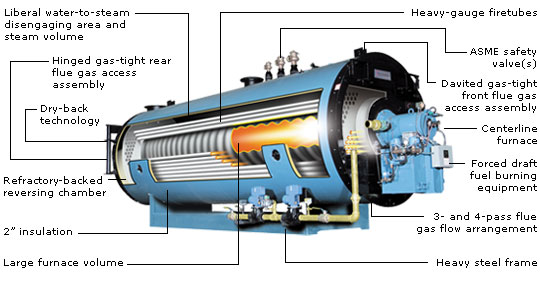

The York Shipley Global Series 400C and 500C three- and four-pass dry-back design accommodates moderate BTUH/CF (Mcal/m³) volumetric furnace heat release rates in comparison to competitive dry-back configurations. The centerline furnace construction reduces vessel thermal stresses.

York-Shipley Global dry-back boilers employ a completely submerged self cleaning centerline furnace which permits for scale formation from water bound solids to drift to the bottom of the boiler for removal during blowdown procedures. The flue gas 'down-draft' design forces hot gases through the lower part of the boiler where cooler water accumulates. Fire-side and water-side access is readily provided. Top longitudinal level service platform ensures safe and secure access, while bottom longitudinal inspection trough ensures unencumbered visual access. The large water volume, as well as a liberal steam disengaging and storage space provides superior performance during continuous and swing load operation. Units include split front and rear fire-side access doors with internal insulation available with heavy duty pivoting hinge arrangements. |

|||||||||||||||

|

|||||||||||||||

|

Series 400C and 500C Packaged Firetube Boilers

York-Shipley Global offers its packaged firetube boiler utilizing a centerline furnace design. Series 400C comprising 4SF-FSHS/BHP (.037m² - FSHS/kW), and Series 500C comprising 5SF-FSHS/BHP (.046m² - FSHS/kW), are available as a three-and four-pass, dry-back configuration. All steel fireside surfaces are completely water-backed. York-Shipley Global product is supported through an extensive worldwide network of sales, service and regional management representatives. |

|||||||||||||||

|